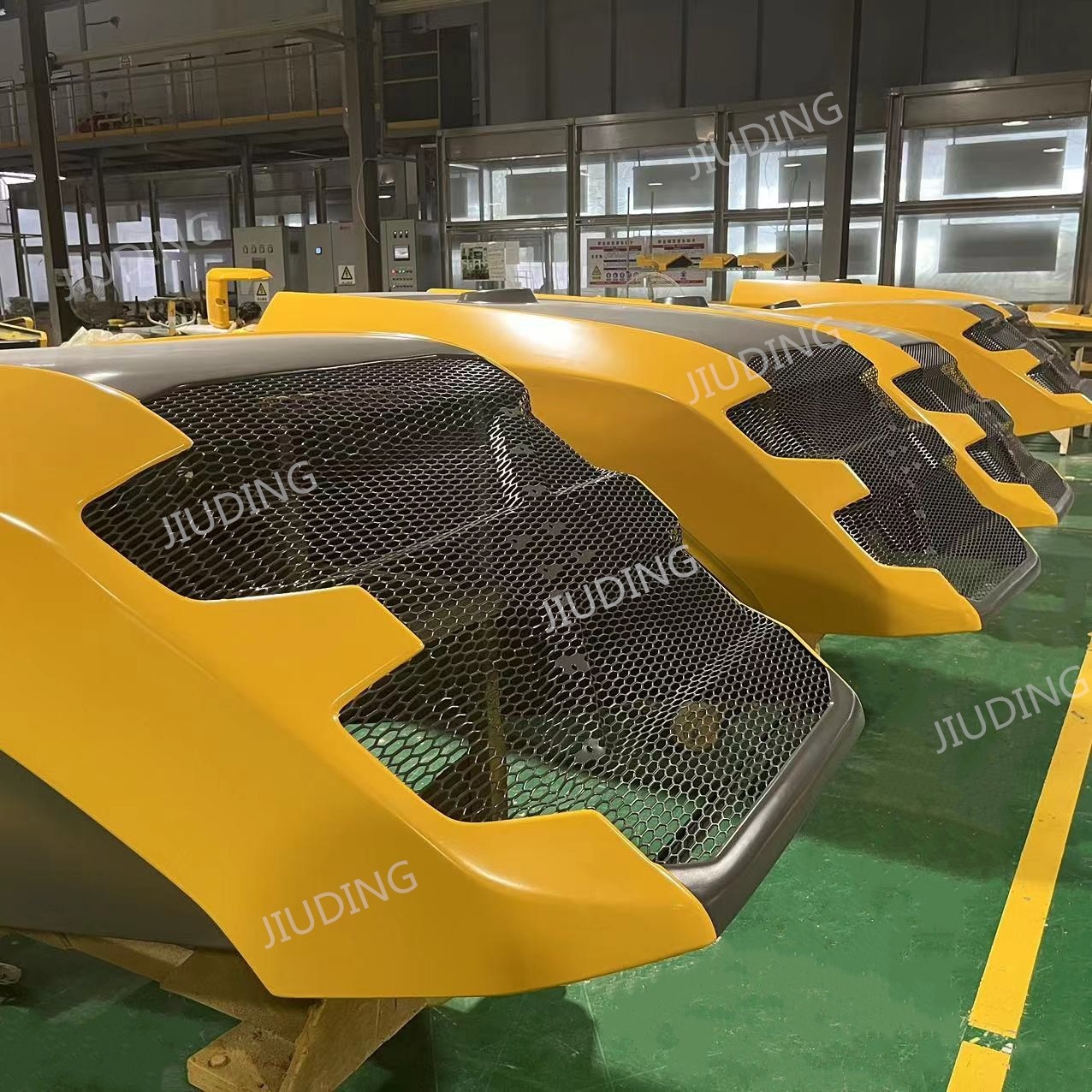

[Copy] The fiberglass hood for excavators

Fiberglass excavator hoods offer a superior alternative to traditional metal designs, combining strength with remarkable environmental resilience. Unlike steel or aluminum, fiberglass resists rust, chemical damage, and moisture absorption, ensuring long-term reliability even in demanding construction environments. This resistance to degradation minimizes wear from mud, debris, and extreme weather, extending the equipment's service life while cutting maintenance expenses.

Customization is another advantage of fiberglass, as its moldable nature allows for precise shaping to match different excavator models. This not only improves visual appeal but also optimizes engine ventilation, enhancing cooling efficiency and machine performance. Additionally, fiberglass acts as an effective noise insulator, lowering operational sound levels—a critical feature for projects in noise-sensitive areas.

UV stability further sets fiberglass apart, as it resists sun-induced fading and weakening, preserving both appearance and functionality over time. By integrating fiberglass hoods, excavators gain a modern upgrade that boosts durability, operational efficiency, and sustainability.

As industries shift toward smarter, longer-lasting equipment, fiberglass hoods are emerging as a preferred choice, delivering cost savings and improved performance for construction businesses. Their adoption reflects a growing focus on innovative materials that enhance machinery longevity while reducing environmental impact.

✧ Product Drawing

✧ Features

The advantages are: high strength, light weight, corrosion resistance, aging resistance, fire resistance, non-conducting, insulation and low recycling. It can replace steel manufacturing construction machinery parts.

![[Copy] The fiberglass hood for excavators Featured Image](https://cdn.globalso.com/jiudingmaterial/fiberglass-parts-for-construction-machinery1.jpg)

![[Copy] The fiberglass hood for excavators](https://cdn.globalso.com/jiudingmaterial/fiberglass-engine-cover1.jpg)

![[Copy] The fiberglass hood for excavators](https://cdn.globalso.com/jiudingmaterial/fiberglass-engine-cover-21.jpg)

![[Copy] The fiberglass hood for excavators](https://cdn.globalso.com/jiudingmaterial/fiberglass-engine-cover-31.jpg)

![[Copy] The fiberglass hood for excavators](https://cdn.globalso.com/jiudingmaterial/fiberglass-parts-for-construction-machinery-21.jpg)