Crafting Excellence with Hand Lay-Up Process

Our skilled craftsmen possess years of experience in applying the resin by hand, ensuring impeccable coverage. This hands-on approach allows for meticulous attention to detail, ensuring consistent quality across every inch of the fiberglass.

Hand Lay-Up, also known as open molding or wet lay-up, is a manual process used to manufacture composite parts. It involves the following steps:

● A mold or tool is prepared, often coated with a release agent to facilitate part removal.

● Layers of dry fiber reinforcement, such as fiberglass or carbon fiber, are manually placed into the mold.

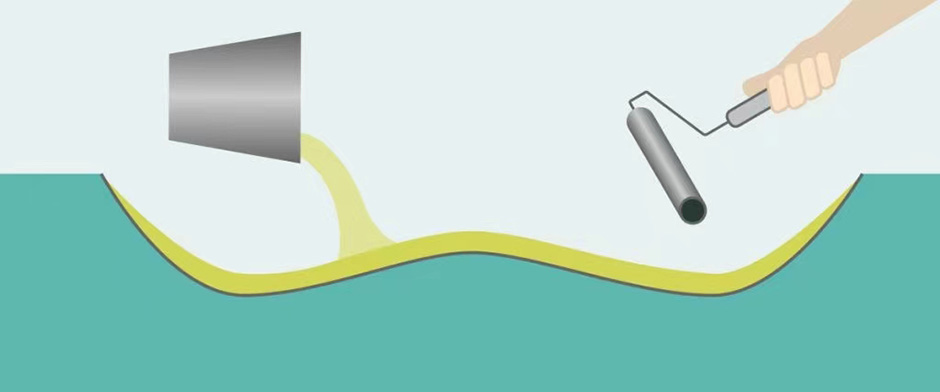

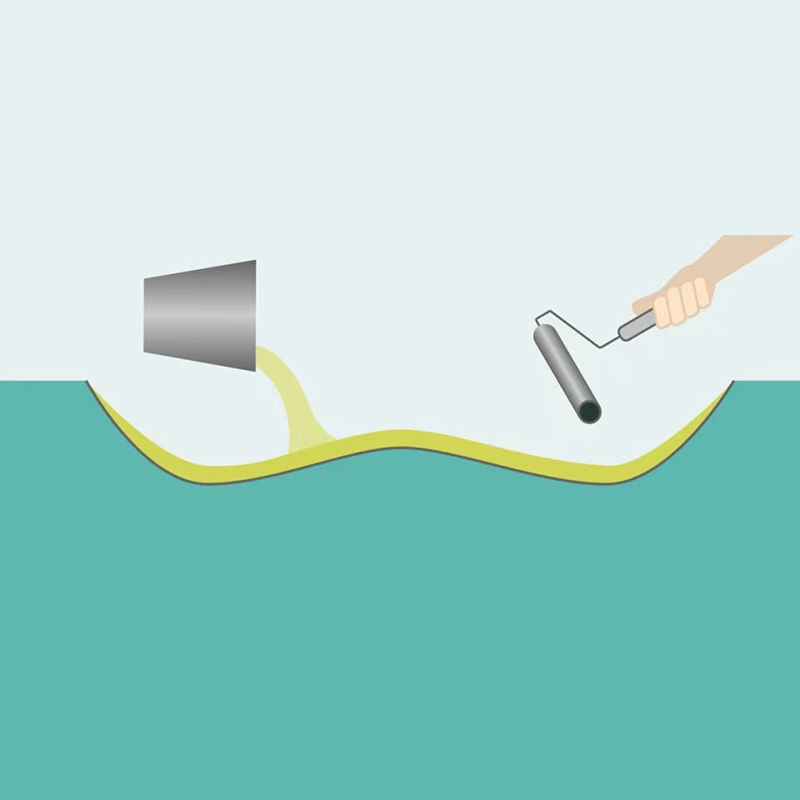

● Resin is mixed with a catalyst or hardener and applied to the dry fibers using brushes or rollers.

● The resin-impregnated fibers are consolidated and compacted by hand to remove air and ensure good wet-out.

● The part is allowed to cure under ambient conditions or in an oven, depending on the resin system used.

● Once cured, the part is demolded and may undergo additional finishing processes.

Hand Lay-Up is a cost-effective and versatile process suitable for producing small to medium-sized parts with moderate complexity. It does not require specialized equipment and can accommodate various fiber types and resin systems. However, it can be labor-intensive and may result in variations in fiber content and resin distribution.

✧ Product Drawing