Fiberglass device housing for medical instrument

Fiberglass device housing for medical instruments offers a robust and versatile solution for protecting and enclosing sensitive medical equipment. These housings are designed to provide a secure and durable enclosure for various types of medical instruments, ensuring their protection from environmental factors and mechanical damage.

Fiberglass device housing for medical instruments is a cutting-edge solution that leverages the exceptional properties of fiberglass materials to create a protective and reliable enclosure for critical medical equipment. The use of high-quality fiberglass ensures that the housing is lightweight, yet exceptionally strong, providing an ideal balance of durability and ease of handling.

The housing is designed to meet the stringent requirements of the medical industry, offering resistance to corrosion, moisture, and chemical exposure. This ensures that the enclosed medical instruments remain safe and functional in various healthcare environments, including hospitals, clinics, and laboratories.

Furthermore, fiberglass device housing can be customized to accommodate specific medical instruments, incorporating features such as mounting brackets, cable management systems, and access panels to facilitate ease of use and maintenance. The housing can also be designed to meet industry standards for cleanliness, sterilization, and electromagnetic shielding, ensuring compatibility with a wide range of medical devices.

In summary, the introduction of fiberglass device housing for medical instruments represents a significant advancement in the protection and management of critical medical equipment, offering a durable, customizable, and industry-compliant solution for the healthcare sector.

The application of fiberglass device housing for medical instruments is diverse and essential for ensuring the protection, functionality, and longevity of critical healthcare equipment. Here are some specific applications for fiberglass device housing in the medical instrument industry:

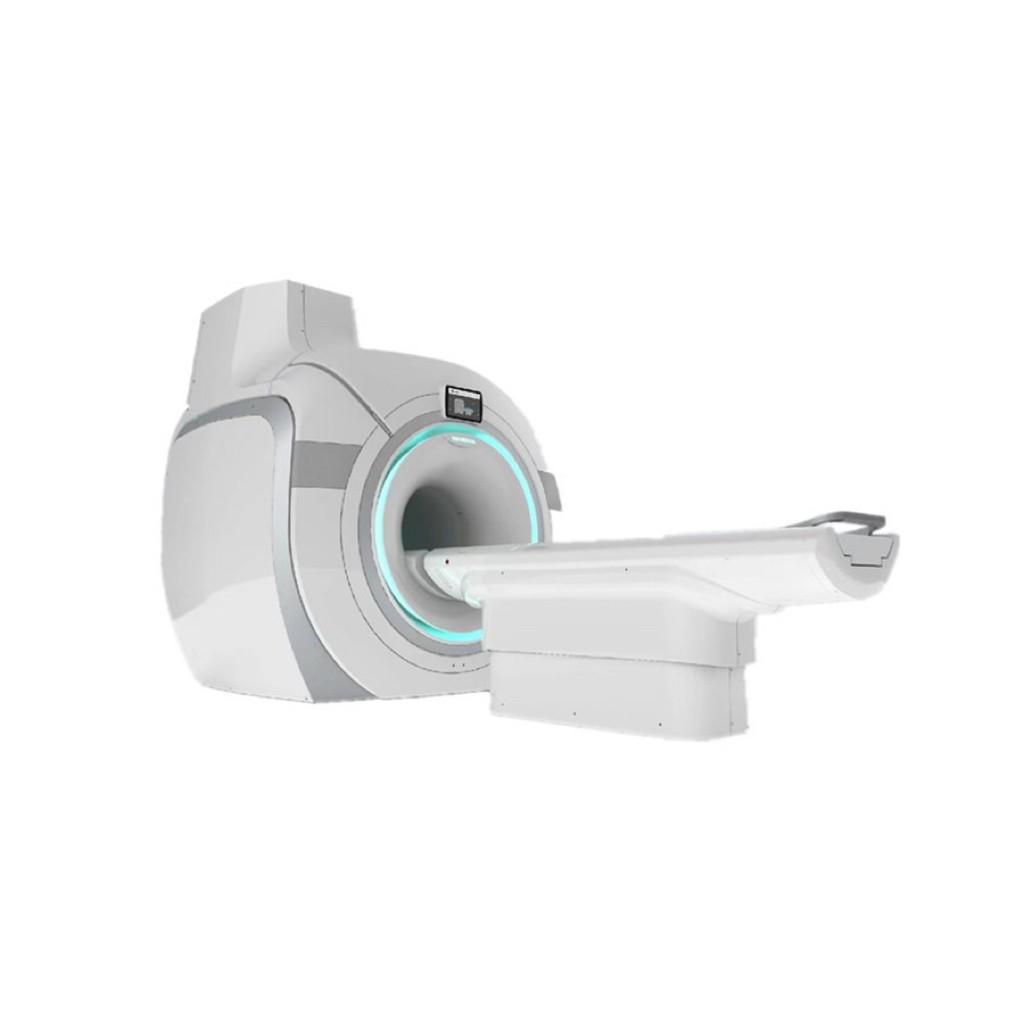

1. Medical Imaging Equipment: Fiberglass device housing can be utilized to encase and protect medical imaging devices such as MRI machines, CT scanners, and X-ray equipment. The housing provides a secure and shielded environment for sensitive electronic components, ensuring the integrity of imaging processes and patient safety.

2. Diagnostic and Monitoring Devices: Fiberglass housing can be employed to house diagnostic instruments such as ultrasound machines, patient monitors, and electrocardiography (ECG) equipment. The housing offers protection against environmental factors and physical damage, safeguarding the accuracy and reliability of diagnostic procedures.

3.Surgical and Laboratory Instruments: Fiberglass device housing is suitable for enclosing surgical instruments, laboratory analyzers, and other precision medical tools. The housing provides a sterile and secure environment, protecting delicate instruments from contamination and maintaining their operational precision.

4. Therapeutic and Life Support Devices: Fiberglass housing can be used to protect therapeutic equipment such as ventilators, infusion pumps, and dialysis machines. The housing ensures the safety and functionality of life-saving devices, even in demanding clinical environments.

5. Customized Instrument Enclosures: Fiberglass device housing can be tailored to accommodate specific medical instruments, incorporating features such as shock absorption, vibration dampening, and electromagnetic shielding to meet the unique requirements of each device.

Overall, the application of fiberglass device housing for medical instruments encompasses a wide range of critical healthcare equipment, ensuring their protection, reliability, and compliance with industry standards for safety and performance.

✧ Product Drawing

✧ Features

The characteristics of FRP products in the medical device industry include high strength, light weight, corrosion resistance, high temperature resistance, good insulation performance, and easy processing. Their excellent physical properties and chemical stability make it an ideal choice for the manufacturing and use of medical devices.