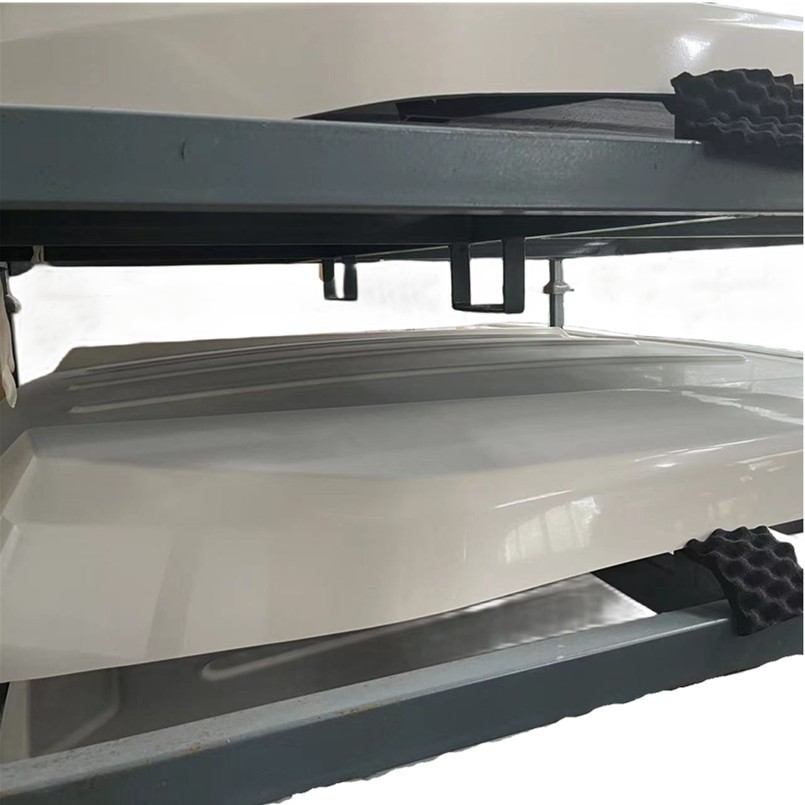

Fiberglass engine cover for construction machinery

The fiberglass engine cover for construction machinery serves several critical applications in the construction industry:

1. Protection: The fiberglass engine cover provides essential protection for the engine and its components, shielding them from debris, dust, and potential impact damage. This protection helps to extend the lifespan of the engine and reduce the need for costly repairs and maintenance.

2. Insulation: The cover helps to insulate the engine from external temperature fluctuations, reducing the risk of overheating and ensuring optimal operating conditions. This is particularly important in construction environments where machinery may be subjected to extreme temperatures and weather conditions.

3. Weight reduction: Fiberglass engine covers are lightweight, contributing to overall weight reduction for the machinery. This can lead to improved fuel efficiency and easier handling of the equipment, especially in construction sites with varying terrain.

4. Durability: Fiberglass is known for its durability and resistance to corrosion, making it an ideal material for engine covers in construction machinery. It can withstand the rigors of construction sites, including impacts and vibrations, ensuring the longevity and reliability of the machinery.

5. Aesthetics: In addition to its functional benefits, a fiberglass engine cover can contribute to the overall aesthetics of the construction machinery, providing a sleek and modern appearance that reflects professionalism and quality.

Overall, the application of a fiberglass engine cover for construction machinery is essential for protecting, insulating, and enhancing the performance and longevity of heavy equipment in the construction industry.

✧ Product Drawing

✧ Features

The advantages are: high strength, light weight, corrosion resistance, aging resistance, fire resistance, non-conducting, insulation and low recycling. It can replace steel manufacturing construction machinery parts.