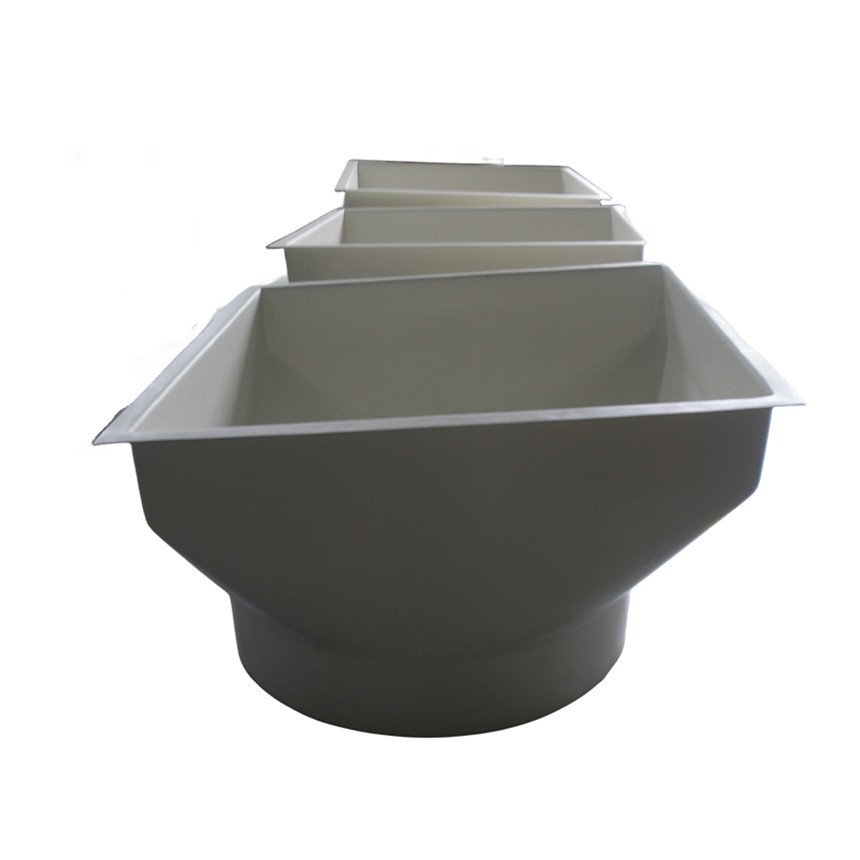

Fiberglass exhaust fan

The fiberglass exhaust fan has a wide range of applications across various industries and environments. Some common applications include:

1. Industrial Ventilation: Fiberglass exhaust fans are used in industrial settings to remove heat, fumes, and airborne particles from manufacturing facilities, warehouses, and workshops. They help maintain air quality and create a safer working environment for employees.

2. Commercial Kitchens: These fans are commonly installed in commercial kitchens to extract cooking fumes, steam, and odors, helping to improve air circulation and maintain a comfortable and hygienic kitchen environment.

3. Agricultural Facilities: Fiberglass exhaust fans are used in agricultural buildings such as poultry farms, livestock barns, and greenhouses to control humidity, remove odors, and provide proper ventilation for animals and plants.

4. Chemical and Petrochemical Plants: In environments where there are potentially hazardous fumes and vapors, fiberglass exhaust fans are used to extract and disperse these substances, contributing to a safer workplace for employees.

5. Laboratories and Cleanrooms: These fans are utilized in controlled environments to maintain air quality, remove contaminants, and regulate temperature and humidity levels.

6. Commercial and Residential Buildings: Fiberglass exhaust fans are also used in commercial and residential buildings to provide ventilation in bathrooms, basements, and other enclosed spaces, helping to reduce moisture and prevent the buildup of odors.

Overall, the versatility, durability, and corrosion-resistant properties of fiberglass exhaust fans make them suitable for a wide range of applications where effective air extraction and ventilation are essential.

✧ Product Drawing

✧ Features

FRP products are widely used in the HVAC industry and can meet the requirements of different scenarios, providing reliable solutions. They can improve system efficiency, extend equipment life and have environmental performance. They meet the energy efficiency and environmental requirements of modern HVAC systems.