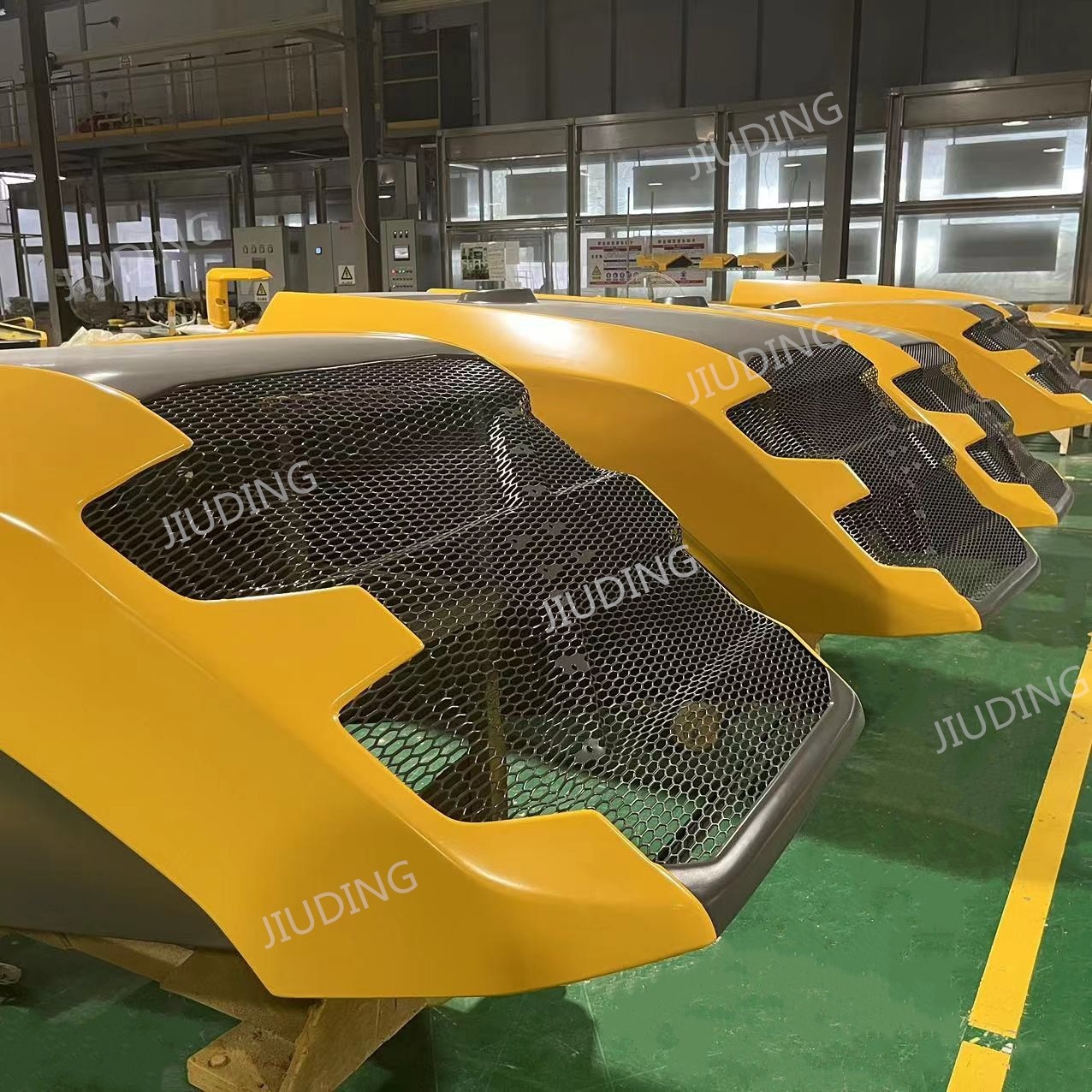

fiberglass fender for construction machinery

Introduction to Fiberglass Fenders for Construction Machinery

In the construction industry, the durability and reliability of equipment are paramount. One critical component that often goes overlooked is the fender system, which plays a vital role in protecting machinery from damage during operation. Fiberglass fenders have emerged as a superior choice for construction machinery, offering a range of benefits that enhance both performance and longevity.

What are Fiberglass Fenders?

Fiberglass fenders are protective barriers made from reinforced plastic composites, specifically designed to absorb impact and prevent damage to machinery. Unlike traditional materials such as rubber or metal, fiberglass combines strength with lightweight properties, making it an ideal solution for various construction applications.

Key Benefits of Fiberglass Fenders

1. Durability: Fiberglass is resistant to corrosion, UV rays, and harsh weather conditions, ensuring that fenders maintain their integrity over time, even in challenging environments.

2. Lightweight: The lightweight nature of fiberglass reduces the overall weight of the machinery, improving fuel efficiency and ease of handling.

3. Impact Resistance: Fiberglass fenders are designed to absorb shocks and impacts, protecting the machinery from potential damage during operation.

4. Low Maintenance: Unlike metal fenders that may require regular painting or treatment to prevent rust, fiberglass fenders are low-maintenance and can be easily cleaned.

5. Customizability: Fiberglass can be molded into various shapes and sizes, allowing for tailored solutions that meet specific machinery requirements.

6. Cost-Effectiveness: While the initial investment may be higher than traditional materials, the long-term savings from reduced maintenance and replacement costs make fiberglass fenders a cost-effective choice.

Applications in Construction

Fiberglass fenders are increasingly being used in various types of construction machinery, including:

- Excavators

- Bulldozers

- Cranes

- Loaders

These fenders not only protect the machinery but also enhance safety on construction sites by minimizing the risk of accidents caused by equipment damage.

Conclusion

As the construction industry continues to evolve, the demand for innovative and efficient solutions grows. Fiberglass fenders represent a significant advancement in protective technology for construction machinery, offering unmatched durability, lightweight design, and low maintenance. By investing in fiberglass fenders, construction companies can enhance the longevity of their equipment, improve safety, and ultimately drive productivity on the job site.

✧ Product Drawing

✧ Features

The advantages are: high strength, light weight, corrosion resistance, aging resistance, fire resistance, non-conducting, insulation and low recycling. It can replace steel manufacturing construction machinery parts.