FRP cooling tower

FRP cooling towers are used in a wide range of industrial and commercial applications for heat rejection and cooling purposes. Some common applications include:

- HVAC Systems: FRP cooling towers are used in heating, ventilation, and air conditioning (HVAC) systems to remove heat from the building’s air conditioning units and chillers.

- Power Plants: They are used in power plants to cool the circulating water in condensers, which is essential for the efficient operation of steam turbines and other power generation equipment.

- Oil Refineries: FRP cooling towers are employed in oil refineries to cool various processes, such as cooling water for heat exchangers and condensing distillation products.

- Chemical and Petrochemical Plants: These cooling towers are utilized to cool process water in chemical and petrochemical plants, where maintaining optimal operating temperatures is crucial for production processes.

- Manufacturing Facilities: FRP cooling towers are used in manufacturing facilities for cooling equipment, machinery, and processes that generate heat during production.

- Data Centers: They are employed in data centers to remove heat generated by servers and other electronic equipment, helping to maintain optimal operating temperatures and prevent overheating.

Overall, FRP cooling towers find applications in diverse industries where efficient heat rejection and cooling are essential for the smooth operation of various processes and equipment.

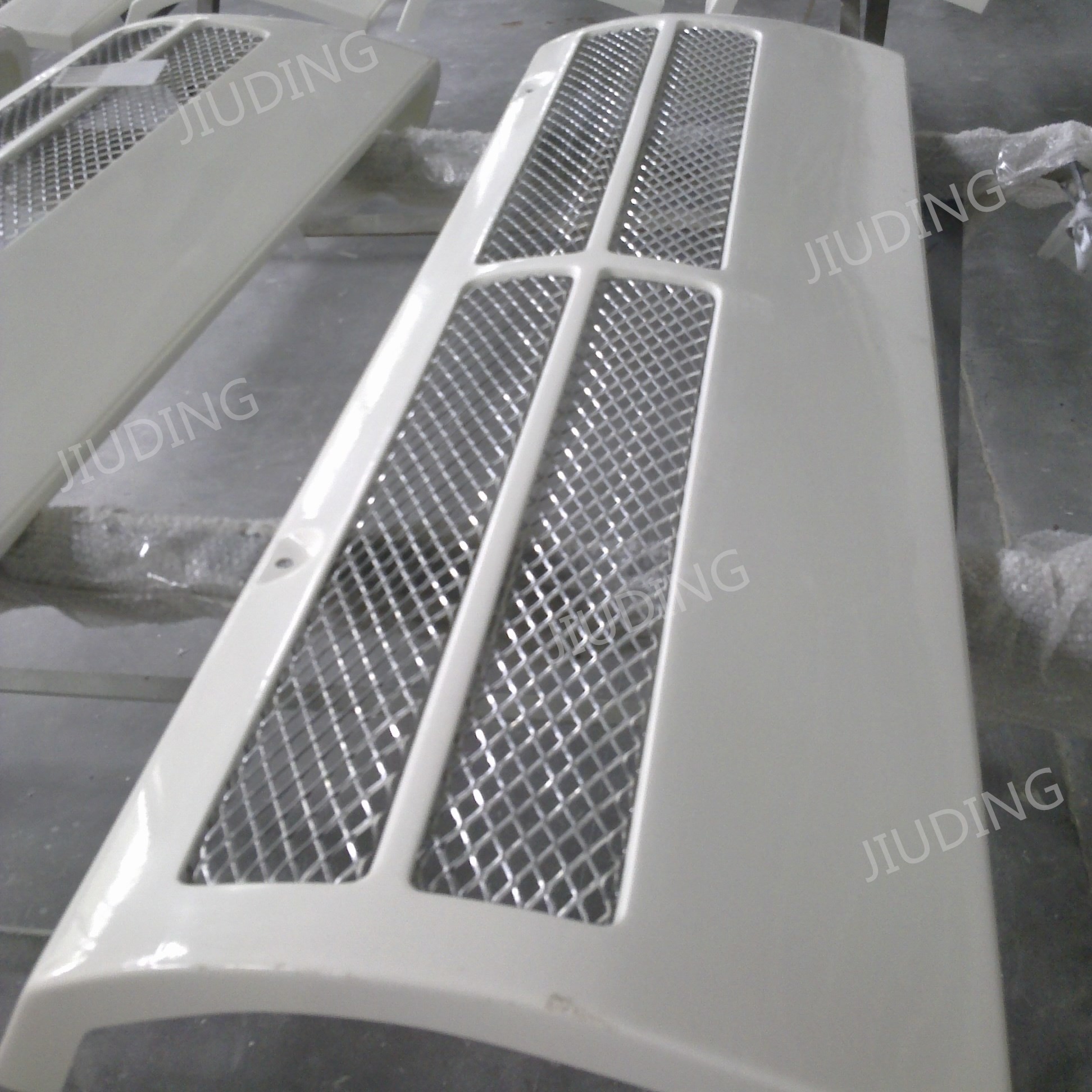

✧ Product Drawing

✧ Features

FRP products are widely used in the HVAC industry and can meet the requirements of different scenarios, providing reliable solutions. They can improve system efficiency, extend equipment life and have environmental performance. They meet the energy efficiency and environmental requirements of modern HVAC systems.

Write your message here and send it to us