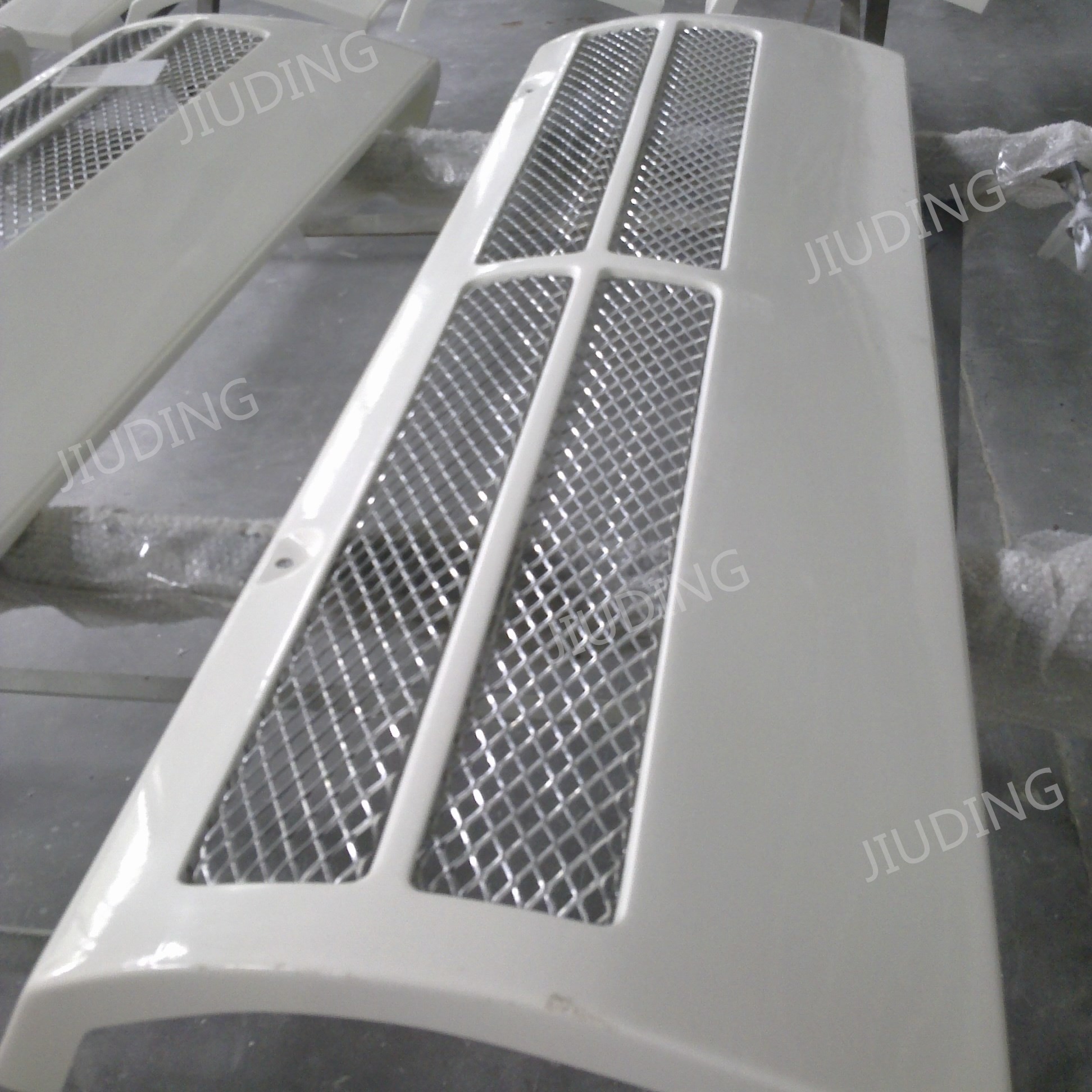

frp exhaust fan

FRP (Fiber Reinforced Plastic) exhaust fans are specialized ventilation devices designed to expel stale air, fumes, and other contaminants from industrial, commercial, and residential spaces. These fans are constructed using fiber-reinforced plastic, a composite material known for its high strength-to-weight ratio, corrosion resistance, and durability. Here’s an introduction to FRP exhaust fans:

Key Features and Benefits:

1. Corrosion Resistance:

- FRP material is highly resistant to corrosion, making these fans ideal for environments where they are exposed to chemicals, moisture, and other corrosive substances. This is particularly beneficial in industries such as chemical processing, wastewater treatment, and marine applications.

2. Durability:

- The robust construction of FRP exhaust fans ensures a long service life, even under harsh operating conditions. They can withstand extreme temperatures and mechanical stress without degrading.

3. Lightweight:

- Despite their strength, FRP exhaust fans are relatively lightweight compared to metal fans. This makes them easier to install and reduces the load on supporting structures.

4. Low Maintenance:

- The non-corrosive nature of FRP means that these fans require less maintenance compared to their metal counterparts. They do not rust or corrode, which reduces the need for frequent repairs and replacements.

5. Energy Efficiency:

- Many FRP exhaust fans are designed to be energy-efficient, helping to reduce operational costs. They often feature aerodynamic designs that enhance airflow while minimizing energy consumption.

6. Versatility:

- FRP exhaust fans are available in various sizes and configurations to suit different applications. They can be used in ducted or non-ducted systems and are suitable for both indoor and outdoor installations.

Applications:

1. Industrial:

- Used in factories, chemical plants, and manufacturing facilities to remove hazardous fumes, dust, and heat, ensuring a safer and more comfortable working environment.

2. Commercial:

- Installed in commercial kitchens, warehouses, and shopping centers to maintain air quality and regulate temperature.

3. Residential:

- Utilized in homes, particularly in areas like kitchens, bathrooms, and attics, to expel moisture and odors, preventing mold growth and improving indoor air quality.

4. Agricultural:

- Employed in agricultural settings such as poultry farms and greenhouses to control humidity and temperature, promoting healthier conditions for plants and animals.

Conclusion:

FRP exhaust fans are a reliable and efficient solution for ventilation needs across various sectors. Their corrosion resistance, durability, and low maintenance requirements make them a cost-effective choice for environments where traditional metal fans may fail. By improving air quality and ensuring proper ventilation, FRP exhaust fans contribute to safer, healthier, and more productive spaces.

✧ Product Drawing

✧ Features

FRP products are widely used in the HVAC industry and can meet the requirements of different scenarios, providing reliable solutions. They can improve system efficiency, extend equipment life and have environmental performance. They meet the energy efficiency and environmental requirements of modern HVAC systems.