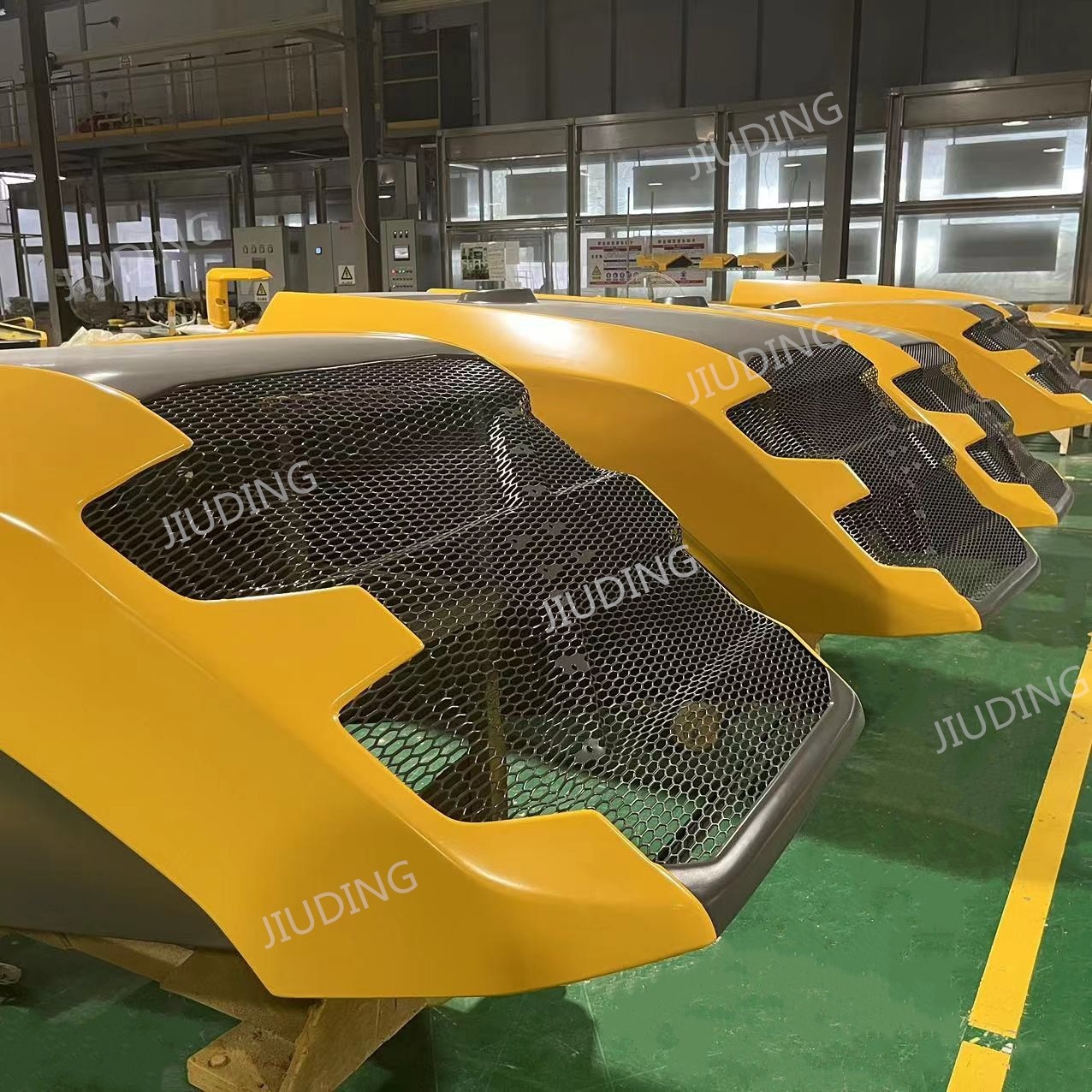

FRP hood

The application for FRP (Fiber Reinforced Plastic) hoods in construction machinery is diverse and crucial for the performance and longevity of the equipment. Here are some key applications for FRP hoods in construction machinery:

- Engine Protection: FRP hoods provide a protective covering for the engine, shielding it from debris, dust, and other environmental elements commonly encountered on construction sites. This protection helps to ensure the reliable and efficient operation of the machinery.

- Component Enclosure: FRP hoods are used to enclose and protect various components such as hydraulic systems, cooling systems, and electrical components, safeguarding them from external damage and extending their lifespan.

- Impact Resistance: FRP hoods are designed to withstand impacts and vibrations, making them ideal for construction machinery operating in rugged environments. They help to prevent damage to vital components, reducing maintenance and repair costs.

- Corrosion Resistance: Construction machinery is often exposed to harsh conditions, including moisture, chemicals, and abrasive materials. FRP hoods offer excellent corrosion resistance, ensuring the longevity of the machinery in such environments.

- Customization and Branding: FRP hoods can be customized to incorporate branding, logos, and specific design elements, contributing to the visual identity of the construction machinery and the overall brand.

Overall, the application of FRP hoods in construction machinery is essential for protecting critical components, ensuring durability, and maintaining the operational efficiency of the equipment in demanding construction environments.

✧ Product Drawing

✧ Features

The advantages are: high strength, light weight, corrosion resistance, aging resistance, fire resistance, non-conducting, insulation and low recycling. It can replace steel manufacturing construction machinery parts.

Write your message here and send it to us