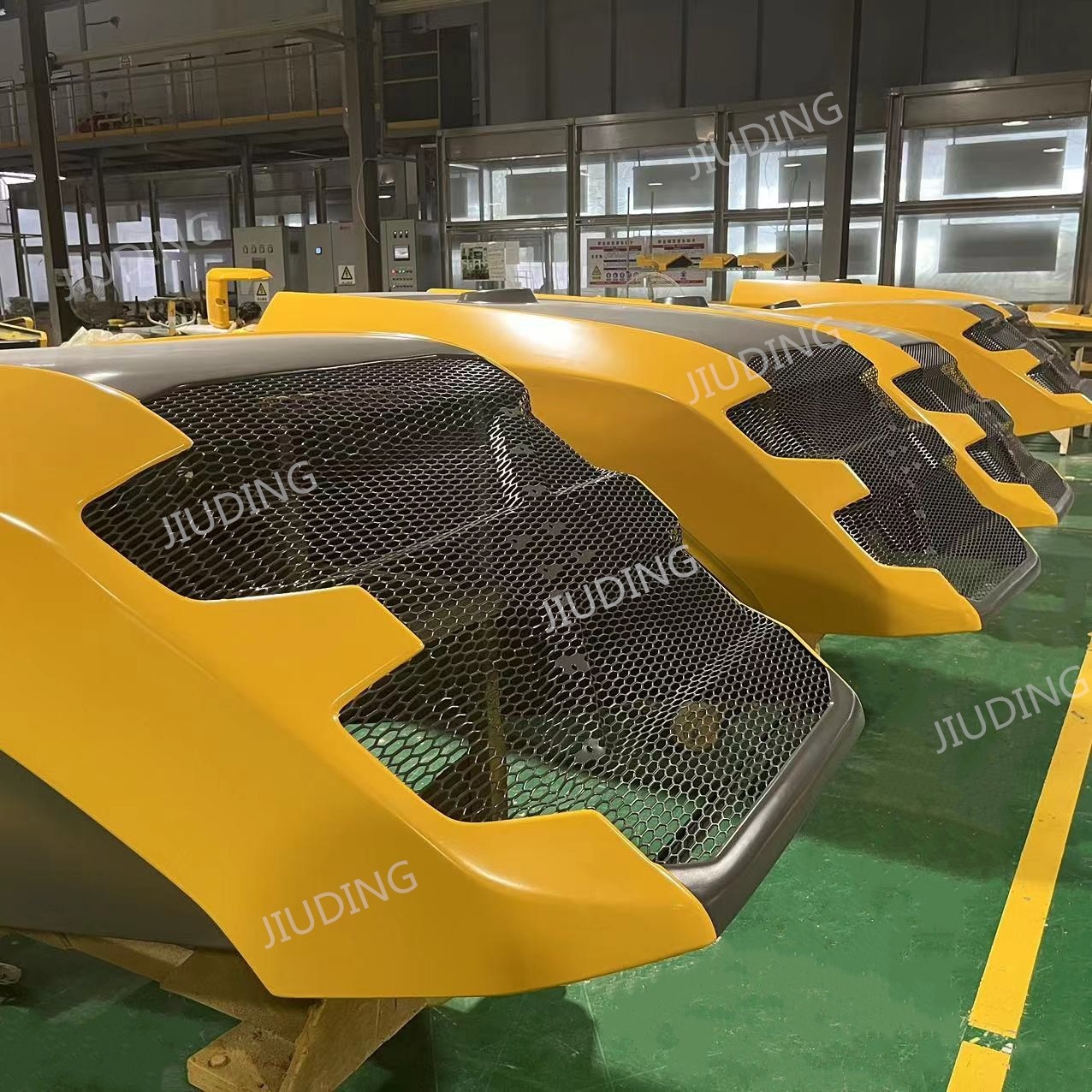

FRP products for construction machinery

FRP, as a new type of composite material, is mainly composed of glass fiber and synthetic resin (adhesive), of which glass fiber is a reinforcing material, synthetic resin is a base material. Then, adding some fillers according to the actual need, can be pressed into, can be injected into and can be manually laminated adhesive. So it is called glass fiber reinforced plastic.

FRP products are widely used in the construction machinery industry.

Body and carriage: FRP can be made into various shapes of shells, covers, and cover plates, which are widely used in the body and carriage parts of construction machinery such as trucks, excavators, loaders, etc.

Oil tank and water tank: Due to its excellent corrosion resistance, FRP is often used to manufacture oil tanks, water tanks and other liquid storage equipment. At the same time, FRP can also withstand higher pressure through reinforced materials and ensure no leakage to improve operational safety.

Earthwork construction equipment components: such as pipeline system lining or diffuser vent.

Guardrail and obstacle protection system: Compared to traditional metal anti-collision guardrails, the contour lines produced by glass fiber composite materials are more beautiful and soft and will cause less harm to personnel or equipment in the event of accidents.

Insulation and soundproofing components: FRP has good insulation and soundproofing performance. It can be used to make insulation and soundproofing components for construction machinery, such as soundproofing covers, insulation boards, etc., to improve the comfort and quietness of mechanical operation.

Appearance decoration: FRP can be used to create surface effects of various colors and textures by adjusting the formula and surface treatment. It can be used for exterior decoration components of construction machinery to improve the aesthetics and quality of the machinery.

The production process of FRP products is simple and there are many production ways. Our commonly molding process involves hand lay-up, vacuum infusion/L-RTM, resin transfer and SMC ( sheet molding compounds).

✧ Product Drawing

✧ Features

The advantages are: high strength, light weight, corrosion resistance, aging resistance, fire resistance, non-conducting, insulation and low recycling. It can replace steel manufacturing construction machinery parts.