FRP ventilation fan

The application of FRP (Fiber Reinforced Plastic) ventilation fans is diverse and includes various industrial, commercial, and residential settings. Some common applications for FRP ventilation fans include:

1. Corrosive Environments: FRP ventilation fans are widely used in environments where traditional metal fans may be susceptible to corrosion, such as chemical processing plants, wastewater treatment facilities, and coastal or marine environments. The corrosion-resistant properties of FRP make these fans ideal for such applications.

2. Agricultural Settings: FRP ventilation fans are utilized in agricultural facilities such as poultry farms, swine barns, and greenhouses to provide proper air circulation and ventilation. The durable and corrosion-resistant nature of FRP makes these fans suitable for the challenging conditions found in agricultural environments.

3. Industrial Processes: FRP ventilation fans are employed in various industrial processes to provide ventilation and air movement. They are used in manufacturing facilities, food processing plants, and other industrial settings to maintain air quality, regulate temperature, and remove airborne contaminants.

4. Commercial Buildings: FRP ventilation fans are installed in commercial buildings, including shopping malls, office complexes, and educational institutions, to ensure proper air circulation and ventilation. They contribute to maintaining a comfortable and healthy indoor environment for occupants.

5. Residential Ventilation: FRP ventilation fans are also used in residential settings, particularly in areas prone to high humidity or where corrosion resistance is essential, such as coastal homes or properties in humid climates.

Overall, the corrosion-resistant and durable nature of FRP ventilation fans makes them suitable for a wide range of applications where reliable air movement and ventilation are required, especially in challenging or corrosive environments.

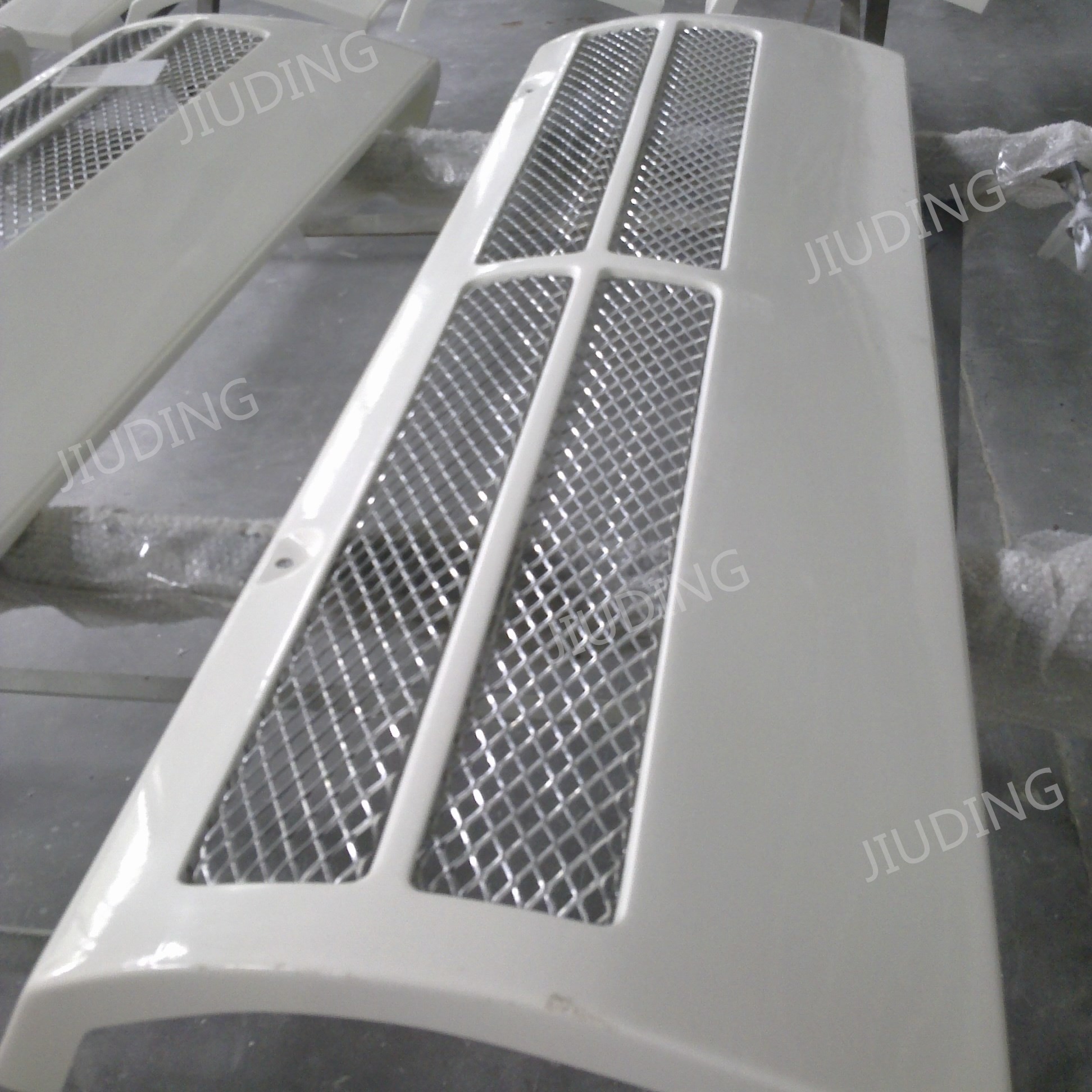

✧ Product Drawing

✧ Features

FRP products are widely used in the HVAC industry and can meet the requirements of different scenarios, providing reliable solutions. They can improve system efficiency, extend equipment life and have environmental performance. They meet the energy efficiency and environmental requirements of modern HVAC systems.