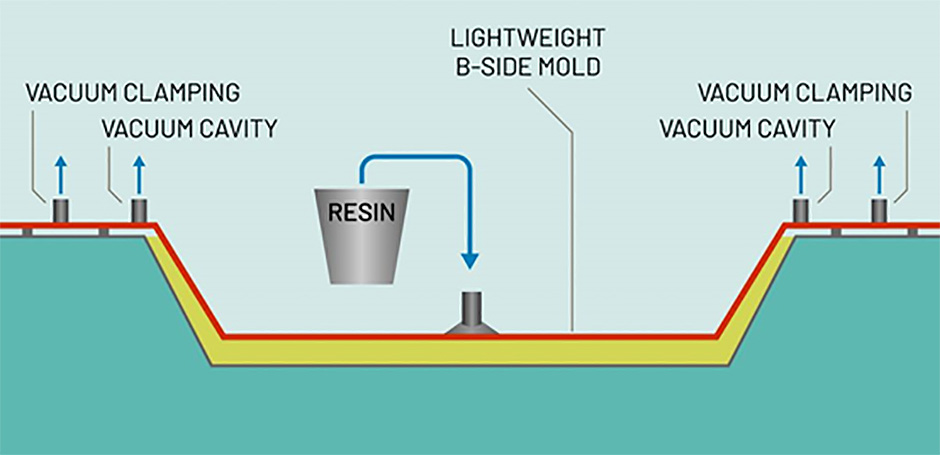

Light Resin Transfer Molding (LRTM)

Why Should You Use Light Resin Transfer Molding (LRTM)?

One of the advantages of LRTM is its ability to produce lightweight parts with excellent mechanical properties. The closed mold system allows for precise control over the resin flow, resulting in consistent and uniform part quality. LRTM also enables the production of parts with complex geometries, as the resin can flow into intricate details and corners of the mold.

Additionally, LRTM offers environmental benefits compared to other manufacturing processes. It generates less waste and emissions, as the closed mold system minimizes resin waste and volatile organic compounds (VOCs) release.

LRTM offers advantages such as improved fiber wet-out, reduced void content, and the ability to produce complex parts with high fiber volume fractions. It also allows for better control over resin flow and minimizes the risk of resin-rich or dry areas in the final part. However, LRTM requires specialized equipment and tooling, and the process can be more time-consuming compared to other molding techniques.

LRTM are widely used in various industries, including aerospace, automotive, marine, and wind energy, for manufacturing high-performance composite parts with excellent strength-to-weight ratios and mechanical properties. The selection of the process depends on factors such as part complexity, production volume, and desired material properties.

✧ Product Drawing