1、 Industry status quo

At present, most of China's transportation construction still uses conventional reinforced concrete and steel as the main construction materials. With the continuous extension of usage time, various aging and damage problems have emerged, and there are problems such as resource waste and poor durability. In order to meet the needs of the current transportation construction field, it is necessary to develop and use more new and environmentally friendly construction materials. Among them, fiber composite materials are increasingly favored by people due to their superior performance, and have been widely used in aerospace, automotive manufacturing, and industrial production.

2、 Technological development trends

From a technical perspective, in response to the different needs of future rail transit development, fiber material technology should be laid out in accordance with the national development strategy:

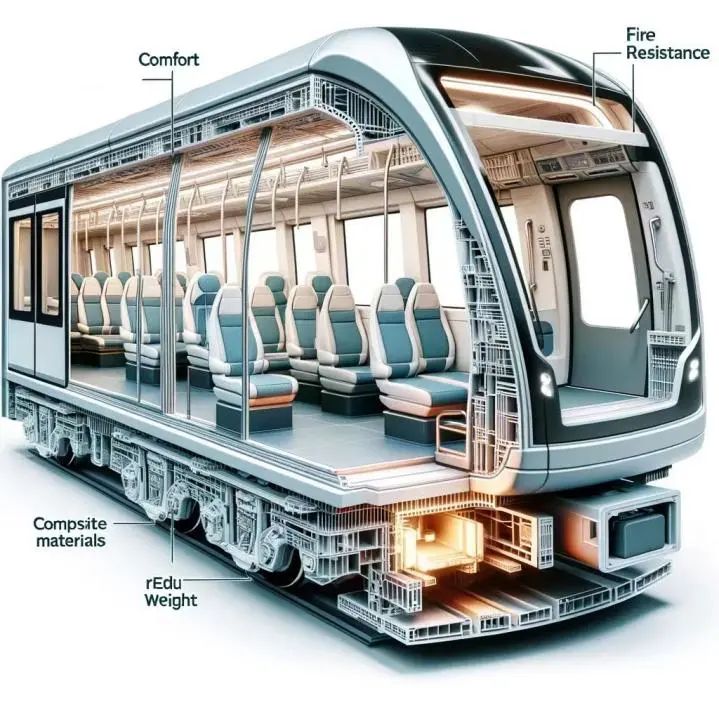

Firstly, based on the high safety requirements of constitutive safety, active and passive protection, and disaster warning, flame retardant polyimide, flame retardant Lyocell fiber, aramid fiber, etc. based on intrinsic flame retardancy, degradability, and low VOC have been developed, achieving high flame retardancy of interior materials; We have developed activated carbon fiber filter materials, melt blown non-woven fabric cellulose filter protective films, and achieved air purification based on nano functional materials.

Secondly, based on the high-quality requirements of comprehensive comfort, human factors engineering, vibration and noise optimization, and smart travel, lightweight composite toughened fiber materials have been developed, which can achieve functions such as shock absorption, noise reduction, insulation, and thermal insulation.

Thirdly, based on the high efficiency requirements of high-speed maglev, interconnected trains, and low resistance high-speed transportation, carbon fiber prepregs, composite material sheets, sheets, industrial components, lightweight shells and components for rail transit and automobiles, drone shells, wings, etc. have been developed and widely used in industries, aerospace, rail transit and other fields.

The fourth is based on the high intelligence demand of intelligent driving, intelligent manufacturing, and intelligent operation and maintenance, utilizing big data and blockchain technology to build fiber material applications throughout the entire lifecycle. With an internet data platform, reliable digitalization of material traceability can be achieved.

The fifth is based on the demand for new energy power, material recycling, low-carbon and low emissions, with a focus on green environmental protection, and has developed interior designs based on recyclable and biodegradable materials.

For the above-mentioned development hotspots, China has gathered relevant industry research teams to tackle them and achieved certain results. For the higher flame retardant and environmental protection requirements of future rail transit equipment, China is developing long-term environmentally friendly flame retardant fibers as a new technology for iterative updates of flame retardant fiber materials. From the perspective of functional masterbatch addition modification, flame retardant modification can be applied to a wide range of chemical fiber products, providing a new path for the exploration and discovery of future flame retardant systems. In terms of specific strength and stiffness, carbon fiber is currently one of the most excellent high-performance fiber materials, and it has been widely used in rail transit equipment. The research team of Qingdao University has developed an efficient, convenient, and low-cost carbon fiber composite friction material by conducting modification research on the surface of carbon fibers. The research team of Sichuan University has designed and developed high-performance polyamide resin. Their team has developed high-temperature resistant semi aromatic nylon (PA6T) and its industrialization technology. The hot deformation temperature of this product exceeds 280 ℃, and it has excellent melt processing fluidity, which can meet the high-performance development of electronic and electrical components towards heat resistance, thin-wall, precision injection molding, and other aspects. In addition, high-performance semi aromatic polyamide thermoplastic elastomers TPA and semi aromatic polyamide have been developed, which have good applications in fields such as automobiles.

High performance fiber based composite materials are often used in non load bearing structures such as driver's interior decoration, driver's console, hood, passenger seat surface, side wall panels, roof panels, and door pillar covers in rail transit equipment. High performance insulation paper is also used in key insulation materials in high-power motors, transformers, and electrical equipment. Taking into account various factors such as excellent material performance and cost, the research team of Wuhan Textile University has developed high-strength and high modulus polyphenylene sulfide and liquid crystal polyarylester fibers, which have been promoted and applied in rail transit equipment.

3、 Market situation

From a market perspective, rail transit equipment is an important component of China's high-end manufacturing field and a major battlefield for independent innovation. From the perspective of segmented market structure, China's rail transit equipment industry can be divided into railway transportation equipment and urban rail transit equipment.

In short, the composite materials field in China's rail transit industry is facing many challenges and opportunities. In the future, with the development and application of new material technology, it is expected to achieve higher safety, comfort, and efficiency of rail transit, while also paying more attention to environmental protection and sustainable development.

Post time: Dec-01-2023