Compared with steel, glass fiber reinforced composite materials have a lighter material and a density less than one-third of that of steel. However, in terms of strength, when the stress reaches 400MPa, the steel bars will experience yield stress, while the tensile strength of glass fiber composite materials can reach 1000-2500MPa. Compared with traditional metal materials, glass fiber composite materials have a heterogeneous structure and obvious anisotropy, with more complex failure mechanisms. Experimental and theoretical research under different types of loads can provide a comprehensive understanding of their mechanical properties, especially when applied in fields such as national defense equipment and aerospace, which requires in-depth research on their characteristics and mechanical properties to meet their needs in the usage environment.

The following introduces the mechanical properties and post damage analysis of glass fiber composite materials, providing guidance for the application of this material.

(1) Tensile properties and analysis:

Research has shown that the mechanical properties of glass fiber reinforced epoxy resin composite materials show that the tensile strength in the parallel direction of the material is much greater than that in the vertical direction of the fiber. Therefore, in practical use, the direction of the glass fiber should be kept as consistent as possible with the tensile direction, fully utilizing its excellent tensile properties. Compared with steel, the tensile strength is significantly higher, but the density is much lower than that of steel. It can be seen that, The comprehensive mechanical properties of glass fiber composite materials are relatively high.

Research has shown that increasing the amount of glass fiber added to thermoplastic composite materials gradually increases the tensile strength of the composite material. The main reason is that as the glass fiber content increases, more glass fibers in the composite material are subjected to external forces. At the same time, due to the increase in the number of glass fibers, the resin matrix between the glass fibers becomes thinner, which is more conducive to the construction of glass fiber reinforced frames. Therefore, The increase in glass fiber content causes more stress to be transmitted from the resin to the glass fiber in composite materials under external loads, effectively improving their tensile properties.

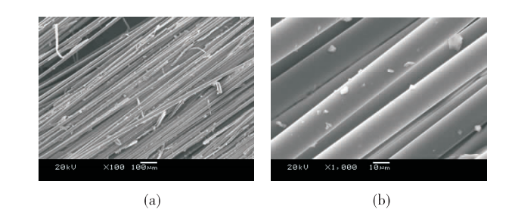

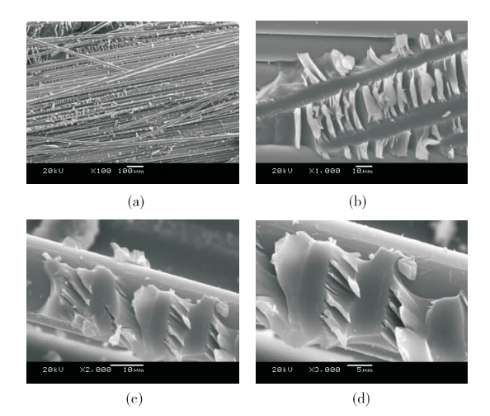

Research on tensile tests of glass fiber unsaturated polyester composite materials has shown that the failure mode of glass fiber reinforced composite materials is the combination failure of fibers and resin matrix through scanning electron microscopy of the tensile section. The fracture surface shows that a large number of glass fibers are pulled out of the resin matrix on the tensile section, and the surface of the glass fibers pulled out from the resin matrix is smooth and clean, with very few resin fragments adhering to the surface of the glass fibers, The performance is brittle fracture. By improving the connection interface between glass fibers and resin, the embedding ability of the two is enhanced. On the tensile section, most of the matrix resin fragments with more bonding of glass fibers can be seen. Further magnification observation shows that a large number of matrix resin bonds on the surface of the extracted glass fibers and presents a comb like arrangement. The fracture surface shows ductile fracture, which can achieve better mechanical properties.

(2) Bending performance and analysis:

Three point bending fatigue tests were conducted on unidirectional plates and resin casting bodies of glass fiber reinforced epoxy resin composite materials. The results showed that the bending stiffness of the two continued to decrease with the increase of fatigue times. However, the bending stiffness of glass fiber reinforced unidirectional plates was much higher than that of casting bodies, and the decrease rate of bending stiffness was slower. There were more fatigue times of cracks appearing over time, indicating that glass fiber has an enhanced effect on the bending performance of the matrix.

With the introduction of glass fibers and the gradual increase in volume fraction, the bending strength of composite materials also increases accordingly. When the fiber volume fraction is 50%, its bending strength is the highest, which is 21.3% higher than the original strength. However, when the fiber volume fraction is 80%, the bending strength of composite materials shows a significant decrease, which is lower than the strength of the sample without fiber. It is generally believed that, The low strength of the material may be due to internal microcracks and voids blocking the effective transfer of load through the matrix to the fibers, and under external forces, microcracks rapidly expand to form faults, ultimately causing damage.The interface bonding of this glass fiber composite material mainly relies on the viscous flow of the glass fiber matrix at high temperatures to wrap the fibers, and excessive glass fibers greatly hinder the viscous flow of the matrix, causing a certain degree of damage to the continuity between the interfaces.

(3) Penetration resistance performance:

The use of high-strength glass fiber reinforced composite materials for the face and back of reaction armor has better penetration resistance compared to traditional alloy steel. Compared with alloy steel, glass fiber composite materials for the face and back of explosive reaction armor have smaller residual fragments after detonation, without any killing ability, and can partially eliminate the secondary killing effect of explosive reaction armor.

Post time: Nov-07-2023